Related Products

Silica gel desiccants absorb moisture, protect items from humidity, prevent mold, and keep products dry.

Silica gel commonly appears as beads or in granular form and come in a variety of sizes and grades for various applications.Generally, silica gel is used to remove water from process streams. In natural gas processing for example, there are specialized silica gels that help separate light hydrocarbons by reducing the dew point, while simultaneously dehydrating natural gas and gasoline. its advantage is hemically stable,flame-resisting.Insoluble in any solvent except strong alkali or hydroelectric acid.

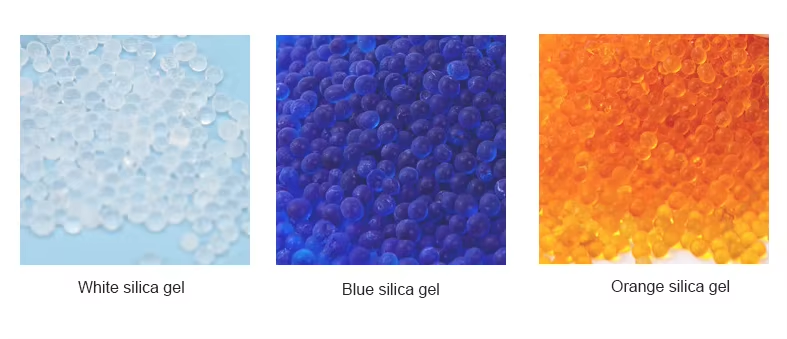

Silica gel: White( non-indication), Blue(indicates as pink), Yellow(indicates as green), and more options…

Classification | Chemical Auxiliary Agent |

CAS No. | 112926-00-8 |

Other Names | Silica gel bead |

Place of Origin | China |

Type | Adsorbent |

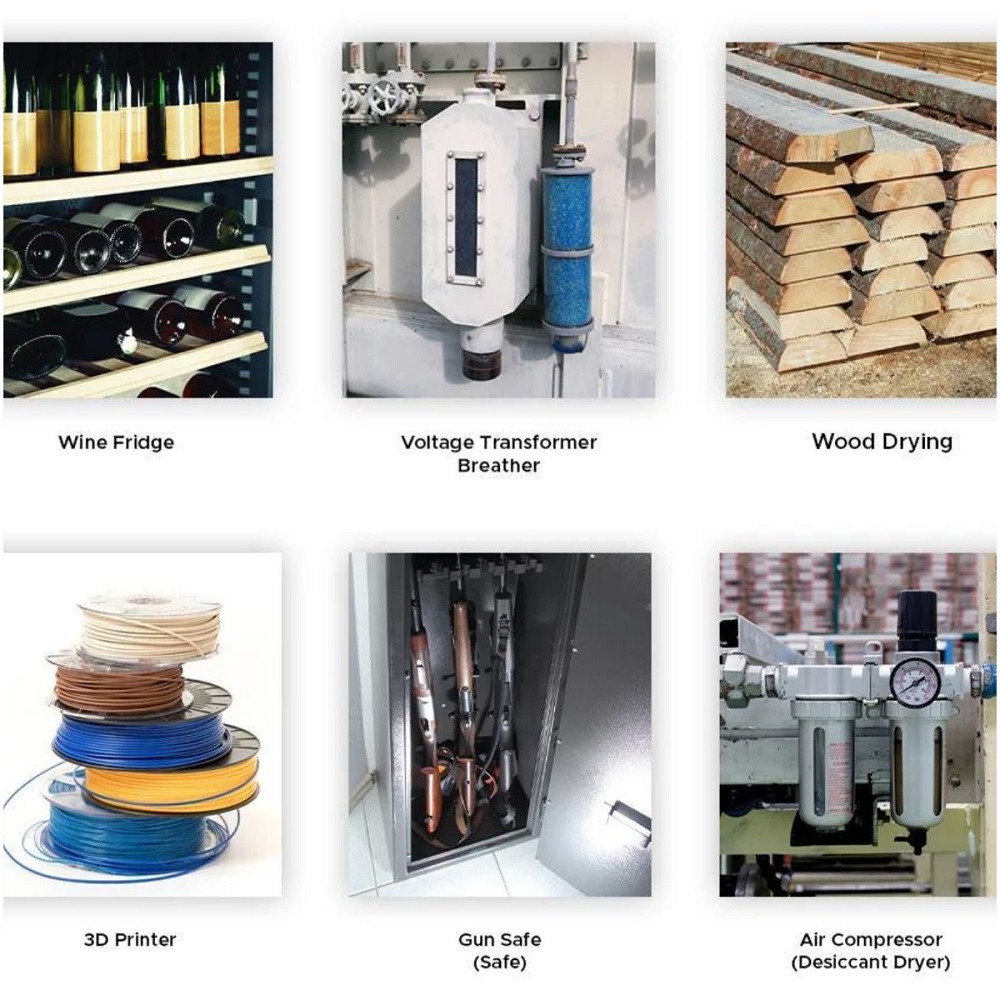

Usage | Mainly used of separating light hydrocarbon from natural gas, the product can reduce dew point of hydrocarbon to produce natural gas gasoline , drying natural gas at the same time .Add 20% (wt) HY-W as the protective layer if water drip exits in separation system. In addition,it can be used as common dryer ,catalyst and its carrier ,variable –pressure adsorption separation agent (PSA). As variable-temperature adsorption separation agent (TSA) at higher temperature, it performs especially suitable. |

Brand Name | MHY Silica Gel Beads |

Product Name | Silica Gel Desiccants Indicating Silica Gel Beads |

Size | 0.5-1mm 2-4mm 3-5mm 4-8mm |

Bulk Density | 780 g/l |

Specific Space Area | 650-800 m2/g |

Application | Coating Auxiliary Agents, Electronics Chemicals, Leather Auxiiliary |

Pore Volume | 0.35-0.45 ml/g |

Thermal Conductivity: | 0.63 KJ/m.hr.℃ |

Quality Management | ISO9001, ISO14001, OHSAS18001 |

Other name | Silica gel |

Appearance | White, Orange or Blue |

White, non-indicating silica gel is a versatile desiccant commonly used for bulk dehydration, available in both bead and granular forms. It efficiently removes water from gases and liquids, making it suitable for use in PSA and TSA systems. Maintaining a moisture-free environment is essential for many industries, such as during the shipment and storage of dry goods to prevent rusting of instruments, gauges, and equipment. This silica gel is suitable for both static and dynamic applications, offering high physical strength and excellent adsorption capacity.

Indicating Silica gel is available in indicating forms, whether a blue color that turns to pink or a yellow that turns to green. These color indicating silica gels are great for alerting the user when water adsorption capacity has been reach and the product is ready to be regenerated or replaced. These products are ideal product for both static and dynamic applications including use in power transformer breathers and desiccant air dryers.

• used in common desiccant applications to control moisture and humidity

• can handle dynamic applications and offers a high physical strength and adsorption capacity

• changes color as it adsorbs water and reaches adsorption capacity

Cost-Effectiveness: We source the best materials at competitive prices, ensuring you get the most value for your investment.

Global Shipping Solutions: Simplify your logistics with our diverse shipping options, including FOB, CFR, CIF, and even door-to-door delivery.

Verifiable Quality: We prioritize transparency. Upon request, we can provide raw material test certificates and final dimensional statements for complete peace of mind.

Unparalleled Responsiveness: Our dedicated team guarantees a response within 24 hours, often within the same hour of your inquiry.

Inventory and Mill Deliveries: We offer both readily available stock and efficient mill deliveries with minimized lead times.

Customer-Centric Approach: We believe in building trust by offering honest solutions and realistic timelines.

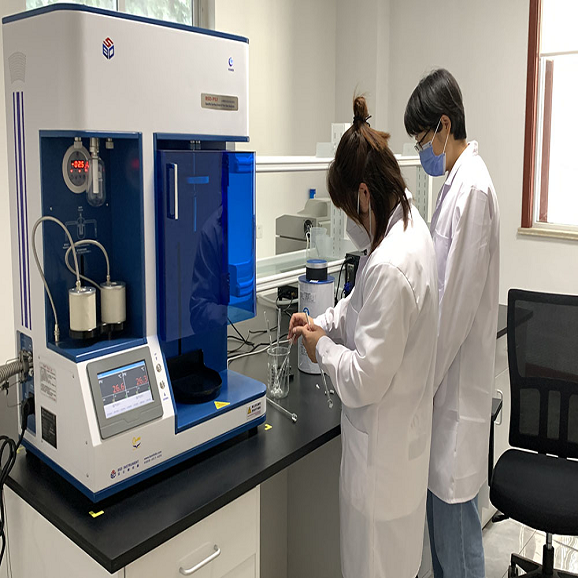

Our silica gel beads undergo strict quality control measures to ensure top-tier performance and reliability:

Moisture Absorption Testing: Evaluates the capacity and speed of moisture absorption to guarantee superior effectiveness in humidity control.

Purity Testing: Ensures the highest grade of silica material, free from impurities, for consistent and reliable use in various applications.

Durability Testing: Assesses the bead’s resistance to physical and chemical wear, maintaining long-term efficiency in diverse environments.

Thermal Stability Testing: Measures the beads’ performance under extreme temperatures, ensuring functionality across a wide range of conditions.

High Moisture Absorption Efficiency: Capable of absorbing up to 40% of its weight in moisture, ensuring superior humidity control.

Wide Application Range: Perfect for industrial, commercial, and household uses, providing protection for electronics, pharmaceuticals, food, and more.

Exceptional Durability: Maintains structural integrity under varying environmental conditions, delivering long-lasting moisture protection.

Chemically Inert: Non-toxic, non-reactive, and safe for use with sensitive products, ensuring reliable performance without compromising safety.

Secure Packaging and Prompt Delivery: We guarantee that our silica gel beads arrive intact and on time, ready for immediate use.

Silica Gel Beads are utilized across a wide variety of sectors for their moisture control and protective properties:

Pharmaceuticals

Electronics

Food Packaging

Textile and Leather

Aerospace

Automotive Parts

Optical Instruments

Shipping and Logistics

Military Equipment

Household Products

A: Our team of skilled engineers and technicians carefully monitors quality control, providing detailed inspection reports for every product batch. We’re also open to adjustments and customizations based on customer requirements.

A: Yes, we offer both OEM and ODM services. We can manufacture products according to your specifications or assist in developing custom designs tailored to your needs.

A: We can provide samples for free, you just need to pay the postage from China to your country

This amount will be returned to you or deducted from your future order amount

A: FOB, CFR, CIF, door-to-door. We’ll advise on the most economical option.

A: We offer stock and efficient mill deliveries with minimized lead times. We’ll provide an estimated timeframe upon confirming your order.

A: T/T 100%, T/T in advance, 30% T/T in advance, the remaining 70% shall be paid before shipment, and irrevocable letter of credit at sight.

A: Yes! We provide raw material test certificates and certificates about the safety

A: Our team guarantees a response within 24 hours, often within the same hour.

A: Contact us directly. We may have it in stock or can help find a suitable alternative.

A: We are committed to customer satisfaction. We’ll provide honest solutions if we can’t meet your exact requirements.

MHY Silica Gel Bead enhances purity by using reverse osmosis membrane technology. This process filters water under pressure, allowing water molecules and ions to pass through while blocking inorganic salts, heavy metals, bacteria, and viruses. The treated water, with a resistivity of up to 30,000 ohms, ensures a high-quality medium for silica gel production.

After filter press filtration, the mud cake has a higher solid content, ensuring excellent separation. The process involves mixed liquid flowing through filter cloth, with solids retained and forming a cake while the clear filtrate passes through. This efficiently filters sodium silicate, producing a high-purity material for silicic acid hydrogel.

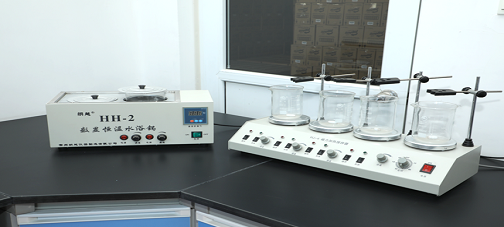

Our technicians conduct isothermal adsorption and desorption analysis to measure surface area, pore volumes, and distributions. We can analyze up to three silica gel samples at once, providing detailed adsorption curves and surface metrics. This method, also used for CO adsorption in high-efficiency silica gel, offers accurate, stable data for advanced product development.

When sodium silicate solution combines with an acid, it forms a gel-like silicic acid. This gel reaction is crucial as it determines the porosity and moisture absorption capacity of the resulting silica gel, impacting its overall performance.

Once dried, the silica gel undergoes screening and quality checks to verify uniform particle size, high purity, and adherence to moisture absorption standards. After passing inspection, it is carefully packaged for transport to protect it from environmental factors during delivery.

Throughout the production process, rigorous quality control measures are implemented. This includes visual inspections, dimensional checks, and mechanical testing (such as tensile strength tests). The image likely represents part of this quality control process, ensuring each wire rope meets the specified standards.

Founded in 1989, our company has become a trusted leader in providing high-quality silica gel bead solutions for a diverse range of industries. We specialize in sourcing, designing, and manufacturing custom silica gel products that offer superior moisture control and preservation. Our clients include buyers, engineers, quality control managers, and product developers who rely on our expertise to deliver results that consistently surpass expectations.

Our team is passionate about moisture control technology and committed to forming long-lasting relationships with our customers. We strive to be a reliable part of their supply chain, ensuring that our silica gel beads meet the highest industry standards. With our advanced in-house testing and material analysis equipment, we meticulously test and certify all products for optimal performance and safety.

We cater to a wide variety of industries, including electronics, pharmaceuticals, packaging, food preservation, aviation, automotive, defense, and textiles. In addition to silica gel beads, we offer a range of complementary solutions to suit your specific moisture control needs.

Located in Taian City, Shandong Province, China, our production facility is equipped to handle projects of any scale. With a global network of trusted partners, we are able to offer competitive lead times and dependable delivery schedules. As we continue to expand beyond 2020, we remain dedicated to creating new opportunities for our talented and passionate team while providing innovative solutions to meet the ever-evolving needs of our customers.

Silica gel desiccants absorb moisture, protect items from humidity, prevent mold, and keep products dry.